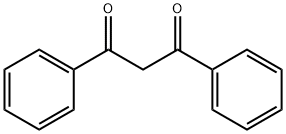

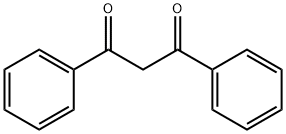

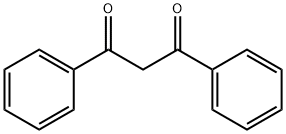

Products Details

Quality index: Appearance: light yellow crystalline powder Content: ≥ 99% Melting point: 77-79 °C Boiling point: 219-221 °CMM Hg Flash point: 219-221 °C / 18mm Instruction: 1. It is widely used as a kind of nontoxic thermal stabilizer for PVC and 1,3-diphenyl acrylonitrile (DBM). As a new auxiliary heat stabilizer for PVC, it has high transmittance, non-toxic and tasteless; it can be used with solid or liquid calcium / zinc, barium / zinc and other heat stabilizers, which can greatly improve the initial coloring, transparency, long-term stability of PVC, as well as precipitation and "zinc burning" during processing. Widely used in medical, food packaging and other non-toxic transparent PVC products (such as PVC bottles, sheets, transparent films, etc.). 2. Introduction of calcium and zinc stabilizers: (traditional stabilizers such as lead salt stabilizers and cadmium salt stabilizers) have the disadvantages of poor transparency, initial color difference, easy cross contamination and toxicity. Zinc and cadmium are non-toxic stabilizers. It has excellent thermal stability and lubricity, excellent initial coloring and color stability. The thermal stability of pure calcium / zinc stabilizer is poor, so a variety of compounds should be compounded according to the processing technology and application of the product. Among the auxiliary stabilizers, β - diketones (mainly stearoyl benzoyl methane and dibenzoyl methane) are indispensable in calcium / zinc composite stabilizers. Synthetic method The original industrial production process was as follows: using solid sodium methoxide as catalyst, acetophenone and methyl benzoate were reacted by Claisen condensation in xylene to obtain dibenzoylmethane. Because the solid sodium methoxide powder is flammable and explosive, and it is easy to decompose when meeting with water, the solvent must be dehydrated before adding, and then the solid sodium methoxide must be added under the protection of nitrogen after cooling to 35 ℃. The reaction process must be protected by nitrogen, and the use of solid sodium methoxide has great potential safety hazard and great power consumption. The molar ratio of acetophenone: methyl benzoate: solid sodium methoxide was 1:1.2:1.29. The average one-time yield of the product was 80%, and the comprehensive yield of the mother liquor was 85.5%. The new large-scale production process is as follows: 3000l xylene solvent is added to the reactor, 215kg solid sodium hydroxide is added, stirring is started, the temperature is raised to 133 ℃, and the low fraction water is evaporated; then 765kg methyl benzoate is added, the temperature is raised to 137 ℃, 500kg acetophenone is added dropwise, and the reaction temperature is kept at room temperature 137-139 ℃. With the addition of acetophenone, the feed liquid gradually becomes thicker. The by-product methanol is removed from the reaction process and the reaction proceeds in the positive direction. The mixed solvent of methanol and xylene is evaporated. Keep for 2 hours after dropping. When there is almost no distillate, the reaction ends. Packing: 25kg / bag. Storage precautions: store in cool, dry and well ventilated warehouse. Annual capacity: 1000 tons / year

CAS NO:124-02-7,

4-Hydroxybenzaldehyde,

D-Glucuronic Acid Lactone,

CAS:537-55-3,

CAS NO:37764-25-3,

Poly(diphenoxy)phosphazene,

Calcium Beta Hydroxybutyrate,

Acetate Isopropyl,

Potassium Beta Hydroxybutyrate,

Isopropyl Acetate Molecular Weight,