Dichloroacetyl chloride

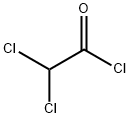

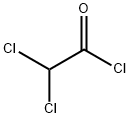

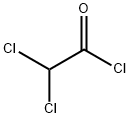

Essential information: Name: Dichloroacetyl chloride CAS NO:79-36-7 Molecular formula: C2HCl3O Molecular weight: 147.39 Structural formula:

Products Details

Featured Products

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours